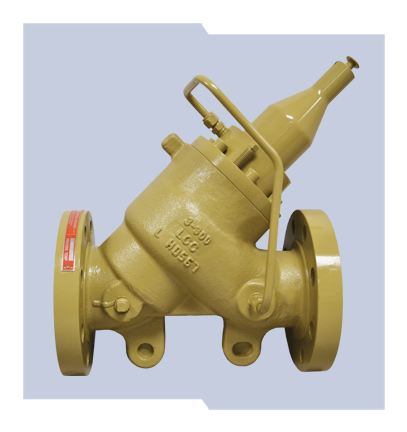

About the Daniel V707 Spring Loaded Back Pressure Control Valve

Delivering Greater Reliability In Pipeline Applications

Combining two valves in one and requiring no pilots or external actuation, the Daniel V707 Spring Loaded Back Pressure Valve offers an innovative way to maintain back pressure while providing an integrated check functionality. The well-known and trusted Daniel Control Valves technology that maintains back pressure has been used in this addition to the Daniel 700 Series Control Valve family of products.

Specifications of the Daniel V707 Spring Loaded Back Pressure Control Valve

| Flange Connections | Valve size: 2″ to 4″ Maximum working pressure at 100º F

Temperature Range: -20º F to 150º F (-29º C to 66º C) |

| Materials of Construction | Valve body: Carbon steel ASTM-A352-GR-LCC Cylinder: 17-4 stainless steel Piston: 304 stainless steel Seat Ring: 303 stainless steel Elastomers: Viton Spring: Chromium silicone (877 Grade A) (877 Grade A) springs Tubing and fittings: 316 stainless steel* *Pressure sensing line needed to perform check valve functionality. Not a pilot line |

| Spring Ranges | Field adjustable, valve differential pressure range

|

| Selection Requirements | 1. Line Size 2. Pressure 3. Temperature 4. Set Point Pressure* 5. Flange Connections *Note: Set point is used to determine spring range. Customer will need to adjust set point in the field. |

Features of the Daniel V707 Spring Loaded Back Pressure Control Valve

- It doesn’t require power.

- There are no diaphragms or stuffing boxes.

- The modular construction means that all internal parts including the seat ring can be removed with the cylinder assembly, without disturbing line connections.

*For service, the line must be drained and the valve isolated.

- High capacity positive shut-off is assured with the 45º body design. ANSI Leakage Class VI (ANSI B16.105 – 1976)

- This check valve incorporates a metal-to-metal seat with a protected o-ring.

- Full working pressure (ANSI 150, 300 and 600)

- It doesn’t need a pilot.

- It’s capable of tamper-proof set point locking.

Daniel’s Control Valves

Daniel has the control valve you need for multiple applications – pipeline control, blending, flow rate or pump control. One basic valve can perform many different functions because all Daniel 700 Series control valves are self-contained and externally pilot-operated. You can choose or change valve capability as required through multiple easily modified pilot arrangements.

Positive sealing, linear valve action, uniform fast response and leak-proof performance are assured through unique design features and unit-built construction. Because the basic valve’s body and internals are the same throughout the line, the spare parts inventory is simplified and costs are reduced.

Using an external pilot for multiple control functions, each 700 Series model is designed for general control applications. The valves can be installed in either a horizontal or vertical line with flow direction vertically upwards.

Download more resources (documents, drawings and videos) here.