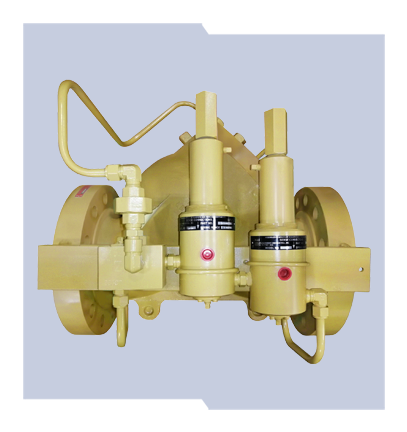

About the Daniel Series 700 External Pilot Operated Liquid Control Valves

Precise Flow Control of Petroleum Products

Daniel Series 700 External Pilot Operated Control Valves let you control the flow of liquid petroleum products, ensuring positive sealing, smooth linear action and uniform speed of response. A single valve body can be equipped with a variety of external pilots allowing one valve to serve multiple functions with this versatile and cost effective line. All internal parts can be removed without interfering with the valve body or connections, simplifying maintenance and maximizing uptime, because of its unit-built construction.

Specifications of the Daniel Series 700 External Pilot Operated Control Valves

| Line Size | DN50 to DN400 (2-in to 16-in) |

| Fluid Type | Liquid |

| Operating Temperature Range | -29º C to +66º C (-20º F to +150º F) |

| Operating Pressure Range | ANSI 150 to 600 |

| Materials of Construction | • Valve Body: Carbon Steel, ASTM A352 GR LCC • Valve Cylinder: DN50 to DN 200 (2-in to 4-in): Stainless Steel, ANSI 150 to 600; DN250 to DN 400 (6-in to 16-in) Carbon Steel, Nickel Coated, ANSI 150 to 600 • Valve Piston: Standard: Stainless Steel |

| Materials of Construction | • Seat Ring: DN50 to DN200 (2-in to 6-in) Stainless Steel; DN300 to DN400 (8-in to 16-in) Carbon Steel, Nickel Coated • O-Rings: Standard: Viton; Optional: Neoprene, EPR, Viton, all Buna-N, Kalrez / Teflon AP (Aggressive Products) |

Features of the Daniel Series 700 External Pilot Operated Control Valves

- Precise flow rate and batch control are achieved with a high-performance balanced piston principle and bias spring design.

- By adjusting the closing speed, damage due to shock pressure is avoided; uniform opening and closing is safeguarded through the main piston.

- The high-capacity, 45º valve body ensures smooth linear action with maximum flow and minimum pressure drop.

- The pressure can be controlled from 10 to 1440 psi (60 to 9928 kPa) within ±2 psi (±13.8 kPa) of setpoint.

- The positive shutoff (ANSI Class VI) and fail-safe closure upon power loss safeguard both equipment and personnel.

- The positive O-ring seal and valve seats are unaffected by fluid viscosity or pressure drop and this improves reliability.

- All internal parts are housed in a cartridge assembly, maximizing uptime with no need to remove the valve from the line.

- The simple design features no diaphragms or stuffing boxes, minimizing wear-related maintenance.

Daniel’s Control Valves

Daniel has the control valve you need for multiple applications – pipeline control, blending, flow rate or pump control. One basic valve can perform many different functions because all Daniel 700 Series control valves are self-contained and externally pilot-operated. You can choose or change valve capability as required through multiple easily modified pilot arrangements.

Positive sealing, linear valve action, uniform fast response and leak-proof performance are assured through unique design features and unit-built construction. Because the basic valve’s body and internals are the same throughout the line, the spare parts inventory is simplified and costs are reduced.

Using an external pilot for multiple control functions, each 700 Series model is designed for general control applications. The valves can be installed in either a horizontal or vertical line with flow direction vertically upwards.

Download more resources (documents, drawings and videos) here.