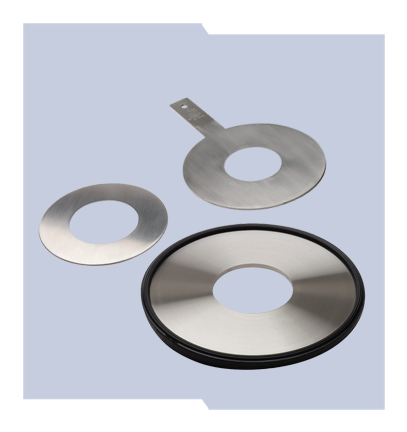

About the Daniel Orifice Plates and Plate Sealing Units

Quality Beyond Compare

Daniel Orifice Plates and Plate Seals exhibit exceptional performance and superior durability. They provide simple and effective solutions for differential pressure measurement and are among the most widely used oil and gas flow measurement technologies. They are available in a variety of line sizes and materials and are compatible with all Daniel fittings – Senior, Junior, Simplex and Orifice Flange Unions. Expertly manufactured to meet or exceed AGA 3/API 14.3 standards, they ensure optimum performance in the worst of conditions while eliminating the possibility of gas leakage or liquid spills. They come with a variety of plate materials and seal options including nitrile (NBR) and PTFE.

Specifications of the Daniel Orifice Plates and Plate Sealing Units

| Line Size | .25-in to 36-in (75 mm to 10970 mm) |

| Uncertainty of Discharge Coefficient | ±0.5% of flow rate |

| Flow Turndown | 10:1 or better |

| Max. Operating Pressure | ANSI 2500 |

| Process Temperature Range | -20°F to +160°F (-29°C to +71°C) |

| Fluid Type | Liquid, gas |

| Process Wetted Material | 316/316L Stainless Steel |

Features of the Daniel Orifice Plates and Plate Sealing Units

- Orifice Plates and Plate Seals are outstanding examples of quality products with exceptional performance and durability that Daniel takes pride in producing. After more than 85 years of service to the oil and gas industry, these simple and effective differential pressure measurement solutions have remained one of the most widely used technologies.

- Compliance with industry standards, and satisfaction of specific application requirements for custody transfer of oil and gas, plus allocation measurement, is ensured with every Daniel Orifice Plate and Seal. With a variety of plate models, and with different orifice plate bore options, Daniel is able to provide the customer with seal options to suit the application type. When using Daniel Orifice Plates and Orifice Seals, customers appreciate the following features.

- Performance and durability are improved by selecting from various integral plate seals.

- A 45 bevel on the borehole periphery enhances the measurement of clean, dry gas and low-viscosity fluids.

- Performance on dirty applications or other challenging fluids is improved with the use of Counter, Segmental, Eccentric, and Quarter Round bores.

- Plate bore size and bevel comply with AGA 3, API 14.3 or ISO 5167, as a result of quality control.

- Troubleshooting is simplified and long-term maintenance is minimized by the use of a very simple measurement device that does not require calibration.

- Measurement accuracy is validated to meet customer design standards.

Download more resources (documents, drawings and videos) here.